-

-

Phone: 413-733-1972

Cost Estimating Software Improves Bid-to-Award Ratio

This article debunks 5 myths surrounding cost estimating for manufacturing

By Heather Tunstall, Assistant EditorIn 1951, when Boston's aerospace and high tech manufacturing sectors were in their infancy, Harvey Lobdell moved a few second-hand metalworking machines into the basement of his suburban home and founded Northeast Manufacturing, Inc. From those modest beginnings, the company has grown into one of the region's leading contract machine shops, adding the latest in machining and computer-aided technology and successfully adapting to the shifts and changes in New England's finicky manufacturing sector. Once Northeast's only employee, the elder Lobdell, now 87, has plenty of company at his shop and is still very active in Northeast management.

Northeast has thrived not only by guaranteeing quality, but also by aggressively cultivating new customers in emerging fields such as aerospace. The general economic and manufacturing slump that came on the heels of September 11, however, has provided an unprecedented challenge to Northeast to keep its sophisticated metalworking equipment busy and its profits up.

"Since 9-11, it seems like there is half as much business out there, and it's twice as competitive to win it," observes Northeast President Chris Lobdell, Harvey's son. Contract bidding and the always-important art of fast and accurate cost estimating are more crucial to company profitability now than ever before. Northeast is relying, more than ever, on its Costimator Computer-Aided Cost Estimating System to produce accurate bids to compete effectively, he says.

"Since 9-11, it seems like there is half as much business out there, and it's twice as competitive to win it," observes Northeast President Chris Lobdell, Harvey's son. Contract bidding and the always-important art of fast and accurate cost estimating are more crucial to company profitability now than ever before. Northeast is relying, more than ever, on its Costimator Computer-Aided Cost Estimating System to produce accurate bids to compete effectively, he says.

Precision parts from Northeast help airplanes and missiles fly through the air, keep space vehicles on the job orbiting earth, function in sophisticated electronic communication equipment, operate in precise scientific measurement devices, and are used in cranial and spinal implants for delicate surgical procedures. In addition to bidding on very expensive prototypes, estimators process a steady stream of Requests for Quotes (RFQs) for parts to be manufactured in lots of as many as 5,000, some on yearlong Just-In-Time (JIT) schedules.

"In times like these, we don't want to lose any business, so we work extra hard and bid extra aggressively," Lobdell says. "At the same time, we don't want to misquote a job, underbid it, and only break even or lose money. Costimator is a valuable tool for making effective quotes, eliminating underbids, and helping us to keep an accurate handle on our manufacturing costs."

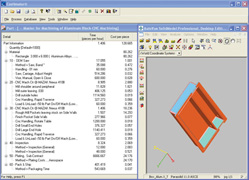

Versatile, Fast, Accurate

The estimating system, purchased in 1987, is a product of MTI Systems, Inc. Using Costimator and instant on-line material pricing options, estimators quickly generate "what if " scenarios for a part's manufacture, costing various manufacturing and tooling options and identifying the fastest and least expensive process. Many quotes are turned around in an hour or less. RFQs for complex parts that require a variety of high tolerance machining operations ? some machined from titanium, exotic stainless steels, and other expensive materials ? are routinely processed within the standard customer-required three-day deadline. The latest versions of the system are written in C++, operate in Windows, and are Open Data Base Compliant (ODBC).

When Northeast engineers initially trained on Costimator, they entered machine times and labor standards into the system's comprehensive database. The "fine tuning" of the system's database is an ongoing process that reflects new tooling and first time jobs.

"We modify our database as we go along, adding new machine times and standards and readjusting existing data as we need to," Charlie Masterson, the company's chief cost estimator says.

Lobdell notes that the system not only provides fast and accurate job quotes for manufacturing a variety of parts on his company's sophisticated CNC machining centers, but it also provides benefits to a variety of areas outside of cost estimating. For instance, Costimator's comprehensive process plans, routings, and other reports support customer service and sales.

The accurate manufacturing times created on Costimator are fed into Northeast's Made2Manage management software, helping to improve the accuracy of shop floor scheduling.

Eliminating Losers

"We want to win jobs, but we need to be absolutely sure that our quotes are on the money," Lobdell explains. "If we win a large job and it ends up costing more to manufacture than we estimated, our profit margin is cut. We even could lose money. Costimator's accuracy lets us bid with confidence."

Northeast relies on Costimator to generate quick, accurate quotes to win profitable jobs.

Northeast relies on Costimator to generate quick, accurate quotes to win profitable jobs.Prior to the purchase of the computerized system, about 40% of the company's total estimates ? produced by manual methods ? were "losers," or were less profitable than estimated, according to Lobdell.

Where manual estimating methods were too inconsistent to accurately perform in a sophisticated, high-volume precision machining work environment, Costimator consistently estimates to within µ5% of actual manufacturing cost. The computer-aided system has helped virtually eliminate "loser" quotes, he says.

The computerized system helps estimators improve profitability in other ways. Estimators easily weed out the RFQs with attached target prices that will translate into minimal profit margins. And in the scenarios where customers come back to Northeast after an initial quote is delivered and ask for a lower "best and final" bid, estimators can refer to Costimator's detailed cost estimates and decline with confidence, Lobdell explains. Success at Northeast is not a function of simply winning more jobs, but of winning profitable jobs and getting them completed on schedule, he says.

Winning Bids, Cutting Costs

Many of Northeast's customers are shopping for more than low prices: they are looking for someone "who can help them, who they can trust," says Masterson. Design engineers don't always understand all the costs associated with machining, he explains, so he frequently uses the Costimator "what if " feature to quickly check for less expensive designs and manufacturing methods. These are recommended to customers. "This capability," Masterson continues, "helps to set the Stoneham machine shop apart from competitors."

The estimator demonstrated how he used Costimator to reduce manufacturing costs and win jobs by describing an estimate he produced for an expensive part for a piece of laser equipment that flew on the NASA space shuttle.

"By playing ?what if,' I was able to suggest fairly subtle part drawing changes that would allow us to use a ¾" endmill, as opposed to a ¼" endmill," he explains. "These changes increased our cutting efficiency and significantly reduced the machine time. We also proposed changes in the design of the corners so less expensive brackets could be used and setup time reduced."

Costimator indicated that these simple changes would cut the customer's target manufacturing cost of $50,000 in half, Masterson reveals. The suggested changes were accepted and Northeast won the bid.

Northeast Manufacturing, Inc.

Stoneham, MA

www.northeastmfg.com

MTI Systems, Inc.

Springfield, MA

www.mtisystems.com

Costimator®

Cost Estimating Software for Manufacturing

-

Cost Estimating Sheet Metal

-

Estimating for Machined Parts

-

Quoting for Machining and Fabrication