-

-

Phone: 413-733-1972

Estimating with Feature Recogntion

Manufacturing Engineering: Why do shops need cost-estimating software?

As Posted On: SME.org

Dave LaJoie

Vice President,

Sales and Marketing,

MTI Systems Inc.Dave LaJoie:

Generally speaking, shops implement cost-estimating software to increase the speed, accuracy and consistency of the estimating and quoting. Cost-estimating software provides them with a database system that 'calculates' material costs and labor hours rather than relying on the experience of the estimator. It standardizes the way a company does its estimating so that inexperienced, as well as experienced personnel, can provide that function. A shop that uses cost-estimating software enables an estimator to put together a quote in minutes, as opposed to hours.

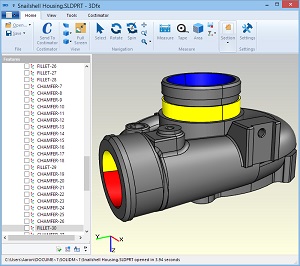

ME: Your Costimator software recently added 3DFX functionality for feature recognition. Describe this capability and what does it offer users?

LaJoie: 3DFX allows our users to increase the speed and accuracy of the estimating process by automatically grabbing or 'extracting' part features and associated properties from a 3D CAD model and importing these features into Costimator, rather than having to manually enter the information. Adding automatic feature recognition technology that instantly identifies part dimensions and features is a significant time saver for estimators. 3DFX supports over 30-plus file formats including AutoCAD, STEP, IGES, Creo, Pro/Engineer, NX, JT, SolidWorks, Solid Edge and Inventor. The software also includes an easy-to-use, rules-based feature modeling tool that enables users to develop their own user-defined parameters as to how part feature information will be translated and then processed/manufactured, based on their manufacturing environment. The 3DFX functionality is a fully integrated add-on for Costimator and is easy to use, even for the inexperienced estimator. We have also added new features, including enhanced cost models, cost/profit reports and SQL Server 2014 compatibility along with 3DFX in the recently released Costimator Version 14.

ME: What key shop problems can be solved with feature recognition cost estimating?

LaJoie: The main problem feature recognition cost estimating solves is the time it takes to generate an estimate. We've seen estimating times lowered by as much as 90% using 3DFX, while substantially improving cost-estimating accuracy and consistency. Up until recently, most shops rarely received solid models for estimating, so feature recognition technology had no benefit for them. Today, over 70% of our customers can get solid models from their customers to estimate from. Our OEM customers, many of whom use our product to cost out new product designs or to get a better understanding of what their parts should cost to manufacture, all have access to 3D models, so 3DFX and feature recognition is an immediate benefit to them.

ME: How does the latest Costimator compare with other available estimating software?

ME: How does the latest Costimator compare with other available estimating software?

LaJoie: The main benefits Costimator brings to manufacturers are the volume of industry-validated cost models and data [speeds & feeds, time standards, etc.] the system contains, the number of manufacturing processes the system supports [machining, fabrication, welding, stamping, castings, forgings, printed-circuit-board assembly, etc.], the flexibility and configurability of the system, and the ability to estimate from a 3D CAD model with 3DFX. The system can be used by both experienced estimators, such as manufacturing engineers, and by people with minimal manufacturing experience, including some design engineering or procurement personnel.

ME: Have many shops adopted cost-estimating software, or is this market still gaining traction?

LaJoie: We have implemented Costimator in over 1600 manufacturing organizations worldwide since 1982, but there are thousands of shops that still estimate by experience alone and have no formal cost-estimating tool or methodology. This antiquated methodology is a costly and less-accurate way to estimate.

ME: What manufacturing companies or industries are best employing this technology?

LaJoie: Cost-estimating software can be used by just about any company or industry that wants to standardize the way they generate a cost estimate, which leads to consistency company-wide rather than estimating by experience, which can be very inconsistent, both from estimator to estimator and from part to part. Costimator is mainly used by metalworking, machining and fabricating manufacturers in industries such as aerospace, agriculture, defense, electronics, medical, heavy truck, energy, oil and gas, and transportation.

Costimator®

Cost Estimating Software for Manufacturing

-

Cost Estimating Sheet Metal

-

Estimating for Machined Parts

-

Quoting for Machining and Fabrication