-

-

Phone: 413-733-1972

Cost Estimating Software Increases Quoting Turnaround

This article debunks 5 myths surrounding cost estimating for manufacturing.

By ToolingandProduction.comThe Landoll Corporation (Marysville, Kansas) chose MTI Systems, Inc.'s Costimator software back in 2007 and since then, has realized 70% faster turnaround times in their cost estimating and quoting, as well as significantly improved quote accuracy.

The Landoll Corporation designs, fabricates, finishes and markets a varied product line of light and heavy equipment in the transportation, material handling, and agricultural industries. Their client list is as impressive as anyone in their industry, servicing such heavyweights such as John Deere, GMC, Snorkel, Caterpillar, Altec and Monosem.

The Costimator software has enabled a 70% faster turnaround on quoting design and manufacturing costs on a variety of large equipment.

Landoll manufactures a diverse array of products including parts and components for earthmoving equipment, trailers, farming industry and tactical vehicles for the US Military. Products they manufacture include their own line of Landoll-owned trailers and tillage, Brillion tillage, Bendi forklift, Drexel forklift, and ICON earthmoving equipment.

The Problem

Because Landoll produces such a broad range of products for an equally eclectic set of industries, the company found itself facing a rather unique challenge: finding a software system that could meet the needs and demands of cost-estimating across a wide-spectrum of industries. The company needed an all-inclusive, flexible system that would produce accurate job quotes and process plans for an array of machining, fabricating and assembly jobs. In addition, they wanted software that would be easy to learn and that would provide cost estimators with the ability to quickly calculate cycle times and costs.

MTI Systems provides cost estimating software and services for the manufacturing industry, serving both suppliers and OEM's.

"Landoll has both manual and CNC machines, and we've diversified our lines to protect us from the up and down economy," said Scott Padgett, Estimator at Landoll who also serves as the company's 'Master Engineer'. "Because we have to quote such a wide spectrum of jobs, we needed an all-encompassing program that could help us meet those needs -- and do it quickly."

How Costimator Helped

Landoll began its search in 2007 and was immediately impressed with what Costimator had to offer. Originally developed in 1982, Costimator was designed to serve as a platform to make cost estimating easier for manufacturing, fabrication and mechanical assembly companies by calculating cycle time and the cost of manufacturing a part or assembly based on the capabilities of the equipment and their shop rates.

Costimator is an all-inclusive, flexible system that produces accurate job quotes and process plans for an array of machining and fabricating jobs.

As time passed, the team at MTI was able to make significant improvements to Costimator, including advanced parametric estimating, enhanced cost estimating methods, should costing, target pricing and more. This allowed Costimator to serve an even wider range of clients than before, including a wide variety of OEM's, defense, and aerospace industries, medical, automotive and consumer product manufacturers. Manufacturing Engineering supervisor Alan Koch participated in the search for the new system, and said his department recognized the benefits immediately.

"The best thing about Costimator is that even when the end-user has minimal computer experience or limited manufacturing knowledge -- he or she can use the program," said Koch. "Our cost estimators work in a time-sensitive and highly competitive manufacturing environment. We found that with Costimator, they could produce consistently accurate estimates, regardless of their manufacturing experience. The software was incredibly accessible in that sense."

MTI Systems has implemented its solutions at over 1,300 companies worldwide with over 10,000 trained users since its inception in 1982

Later that year, Landoll bought and installed the system, and has seen the results multiply year after year since its implementation, some of which include:

- 70% faster turnaround times on estimates

- More accurate quotes

- Increased accessibility to cost-estimating process, leading to greater organizational efficiency

- A comprehensive program that can meet the varied demands of the industries Landoll services

"We get a consistent flow of requests-for-quotes into our department," said Padgett. "With Costimator, we can tweak a lot of our existing cost-models and builds to meet our needs. The models that come with the system are very easy to modify, and creating new ones is a very straight-forward process."

"As our cost estimating has developed using Costimator®, through the implementation and use of more cost models, our estimating and quoting turnaround time, per job, continues to be reduced -- saving us even more time," said Padgett. "Recently I did a quote for a very large fuel tank that took a couple of days instead of an entire week or more! The result: I estimated and won the quote in a matter of a few days compared to weeks or longer. This enabled us to move on to other jobs reducing costs and offering us more opportunities to quote more jobs offering options to add more profits."

Landoll designs and manufactures equipment for John Deere, GMC, Snorkel, and Caterpillar.

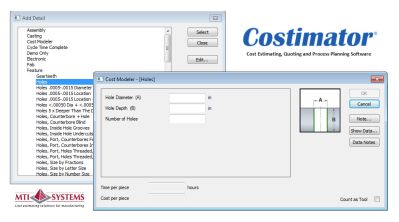

MTI Systems recently released Costimator® version 12 with enhancements that offered more benefits when using "Cost Modeler, the embedded cost model editing tool. While Costimator® is shipped with over 300+ cost models, this tool enables users to create their own process / work center specific to their times. In this update, among other added benefits, a scroll bar was added allowing users to more elaborate information, that being the details that pertain to more complex cost models.

"After building and/or modifying more than 100 cost models, we began to build and structure them with more details and inputs offering more options and time savings for users," remarks Padgett. "We explained to MTI Systems our need to have the ability to scroll through these more complex models, that were significantly longer than typical cost models included out of the box and they provided the solution in their next update. It is quite impressive to get changes made shortly after we requested them."

Costimator®

Cost Estimating Software for Manufacturing

-

Cost Estimating Sheet Metal

-

Estimating for Machined Parts

-

Quoting for Machining and Fabrication